MANUFACTURING

HIGHEST DEMANDS ON QUALITY AND TIGHTNESS

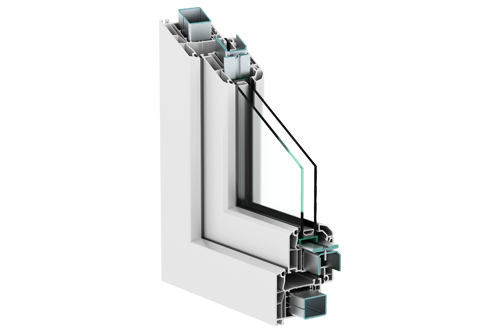

Gebhardt –Stahl slip-on duct connections enable the fast, cost-effective and tight connection of rectangular air ducts. Almost any size and sealing class is possible. Comprising of slip-on duct flanges of different sizes and a variety of different corners, our 4-bolt connection systems allow for the appropriate connecting frame to be produced for every requirement (duct size, volume flow, pressure ratios, air tightness). Flanges and corners are also available made of stainless steel (AISI 304 or AISI 316) or aluminium.

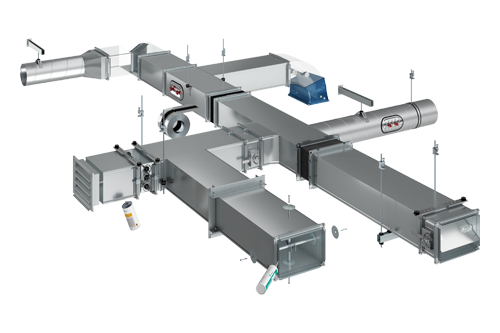

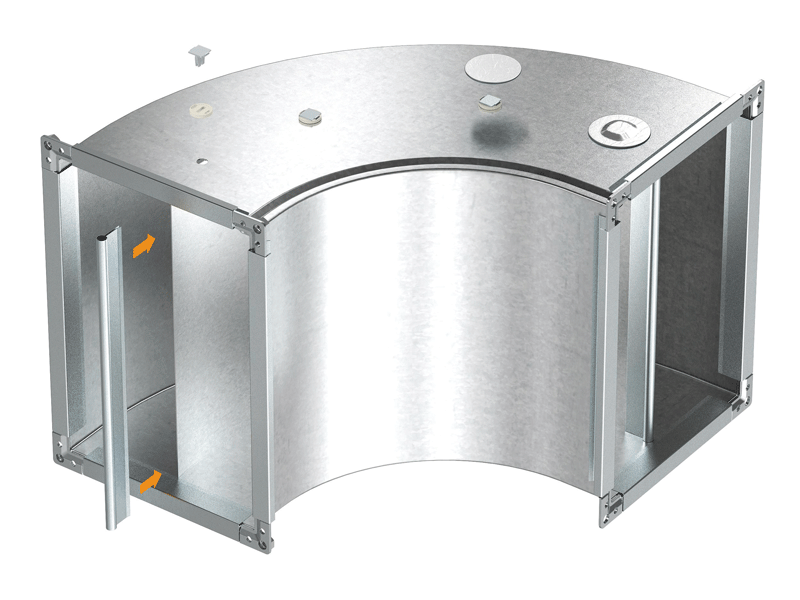

OPTIMISES THE FLOW - REDUCES TURBULENCES AND NOISE

Turning vanes are installed in rectangular ductwork, e.g. in bends or junctions, in order to optimise the air flow. The turning vanes effectively reduce turbulence and consequently, pressure losses and noise. The use of turning vanes is specified by DIN EN 1505 for bends with an angle greater than 45°. As such, the number of vanes depends on duct dimensions. In contrast, for junctions, the German DIN standard does not specify if the use of turning vanes is of any useful purpose there.

Turning vane fasteners, available in galvanised steel and stainless steel, are ideal for fixing the turning vanes. In order to reduce the leakage, all our baffle plugs are already fitted with a mounted sealing washer.

For maximum seal requirements, we provide sealing pads for our turning vane fasteners. Additionally we offer a reinforcement profile for turning vanes for reducing vibrations at the end of the turning vanes.

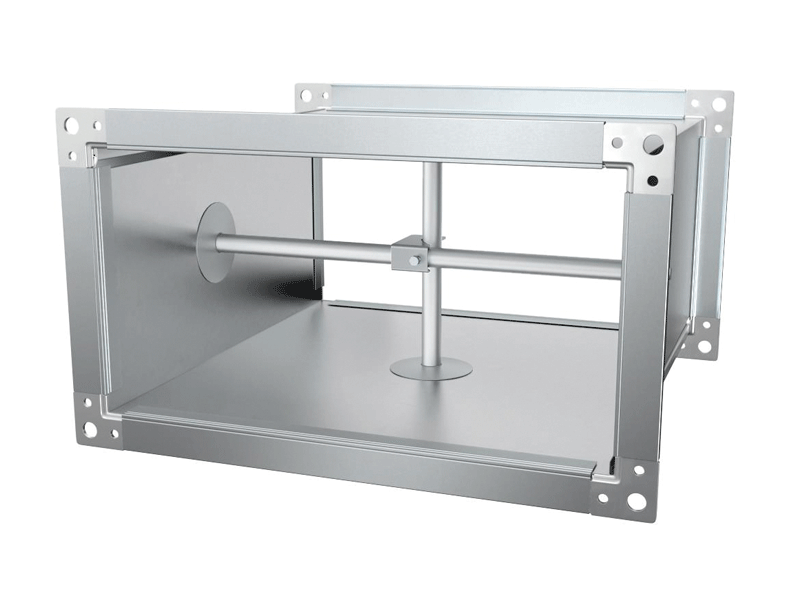

AVOIDS VIBRATIONS AND NOISE

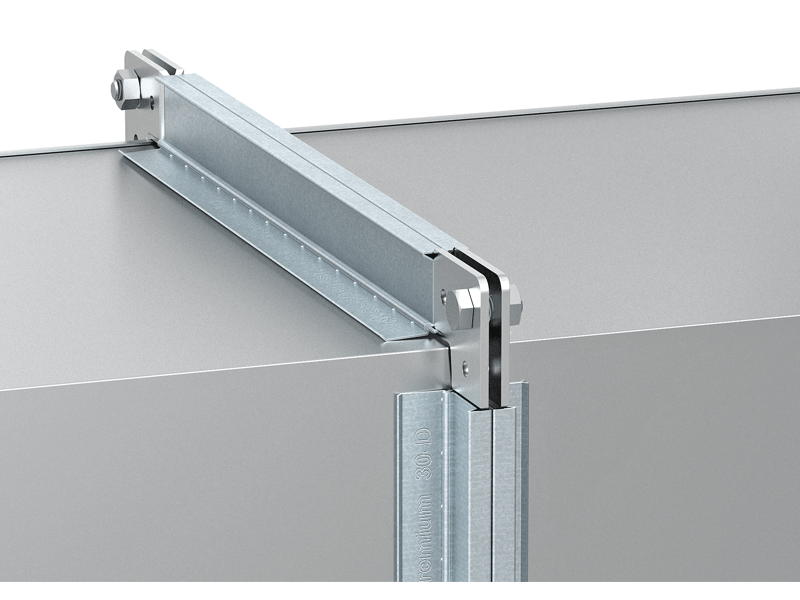

Turbulences and vibrations can cause disturbing vibrational noises to ductwork. In order to avoid these noises, the best possible damping and stiffening of the ductwork is required. Rectangular straight ducts with unfavourable duct cross-sections, with high positive or negative pressure and, of course, in case of large duct cross sections do need reinforcement measures.

Ventilation ducts with a large cross-section and varying excess pressure and negative pressure should be optimally stiffened in order to ensure maximum stability and elimination of flutter. The additional reinforcements then ensure that the duct sections remain dimensionally stable and that the entire ventilation system can be operated smoothly without pressure losses/leaks and, above all, safely.Gebhardt-Stahl reinforcement materials are easy to use and cost-effective.

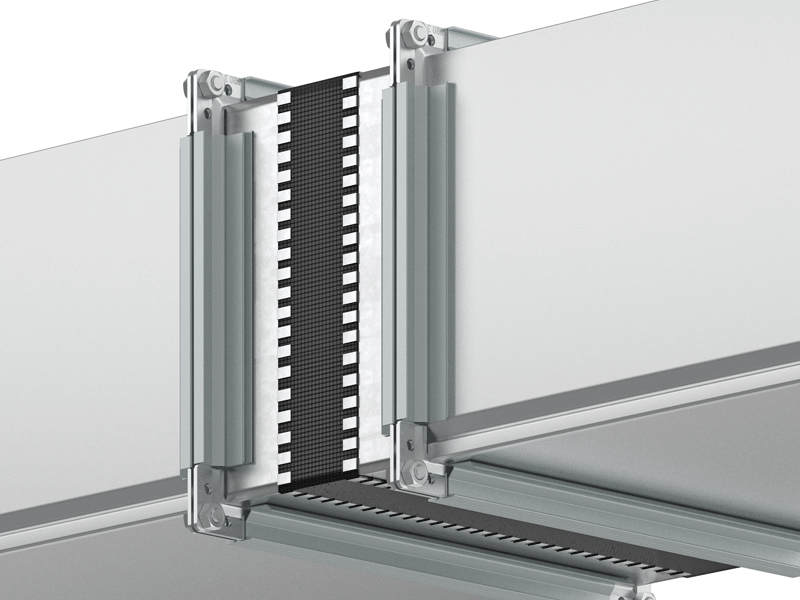

SHEET. FABRIC. SHEET.

Flexible connectors are necessary for making fabric compensators. These compensators help to avoid the transmission of vibrations in spiral or rectangular ductwork and suitable for acoustic decoupling. Thus, flexible connectors frequently serve as a connecting element between devices or fans and ventilation ducts.

Flexible connectors consist of a fabric, e.g. polyester with PVC coating or glass fibre with PU coating, which is secured to sheet metal on both sides. The sheet metal can be made of galvanised steel or stainless steel.

If assembled correctly, the produced compensators are suitable for sealing class C.