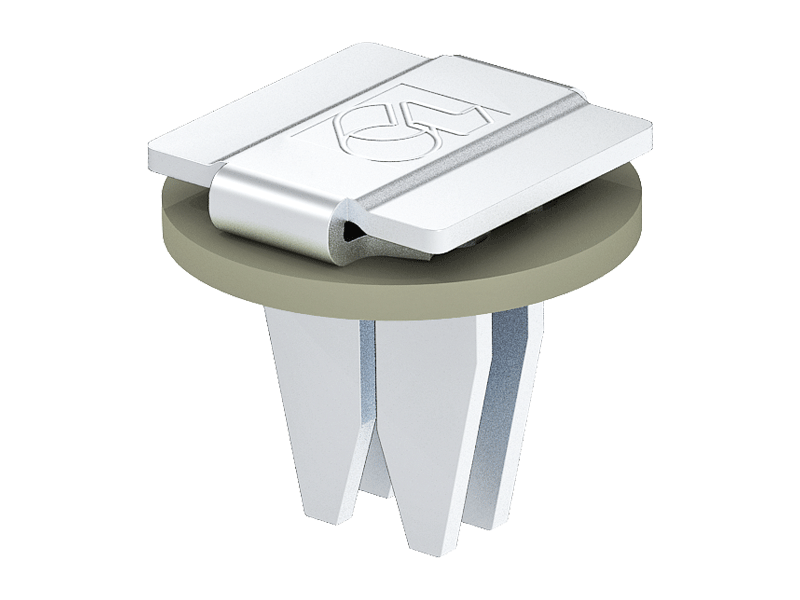

Turning vane fastening

OPTIMISES THE FLOW - REDUCES TURBULENCES AND NOISE

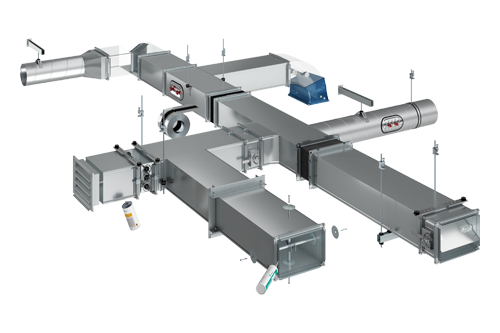

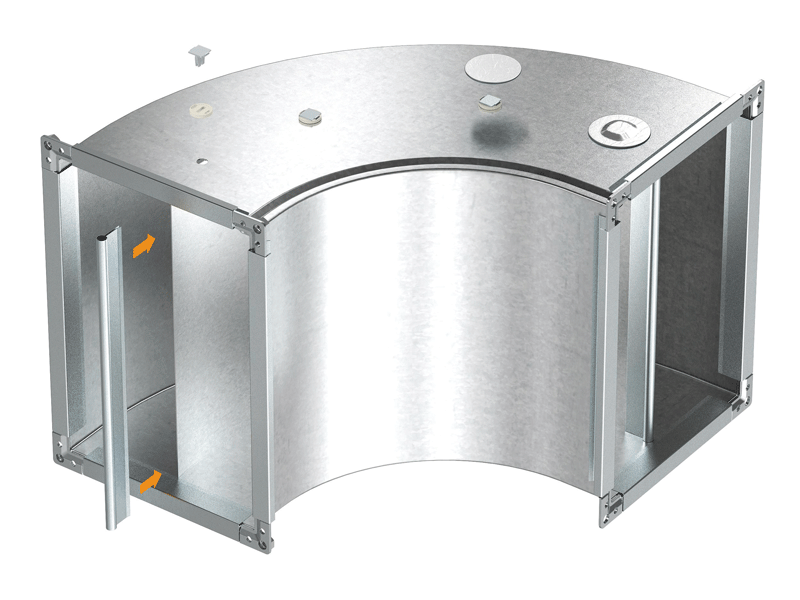

Turning vanes are installed in rectangular ductwork, e.g. in bends or junctions, in order to optimise the air flow. The turning vanes effectively reduce turbulence and consequently, pressure losses and noise. The use of turning vanes is specified by DIN EN 1505 for bends with an angle greater than 45°. As such, the number of vanes depends on duct dimensions. In contrast, for junctions, the German DIN standard does not specify if the use of turning vanes is of any useful purpose there.

Turning vane fasteners, available in galvanised steel and stainless steel, are ideal for fixing the turning vanes. In order to reduce the leakage, all our baffle plugs are already fitted with a mounted sealing washer.

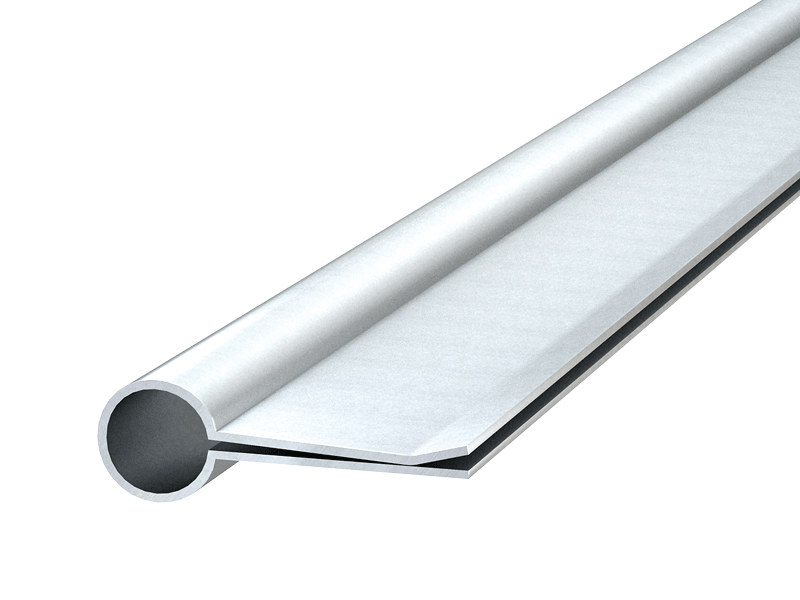

For maximum seal requirements, we provide sealing pads for our turning vane fasteners. Additionally we offer a reinforcement profile for turning vanes for reducing vibrations at the end of the turning vanes.

Application

Ideal for fixing baffles in bends, angles and branches or T-pieces.

Sealing washer

To reduce leakage, all our baffle dowels are provided with a mounted sealing washer ex works.

Sheet thicknesses

Our baffle dowels are suitable for sheet thicknesses from 0.75 mm to 1.25 mm, depending on the design.

OUR EXPERTS FOR HVAC COMPONENTS

Our focus on continuous development has allowed us to grow over the past decades from a supplier of ventilation components to a leading company in the field of air duct profiles and a full-range supplier in the field of ventilation accessories.

In the course of this development, however, one thing has always been in the foreground - the pursuit of professional, high-quality and individual solutions for you, our customers and partners.