Bespoke profiles

Steel profiles or metal sections in general, are used in many areas of daily life and in many different sectors. Cold-rolled profiles play a 'supporting role', not only in the construction industry but in countless other areas as well.

Mostly invisible in their function as building and construction materials, cold-rolled metal sections are also used as a design element in modern architecture.

Gebhardt-Stahl has been working closely with its customers for over 40 years. We have done this in order to produce optimum bespoke profiles for your application.

Materials

We offer profiles in galvanised steel, pickled steel, stainless steel (1.4301, 1.4404, etc.), aluminium and other non-ferrous metals.

Adaptations

Numerous processing operations such as punching, mitre cutting, deburring etc. are part of our portfolio.

Profiles

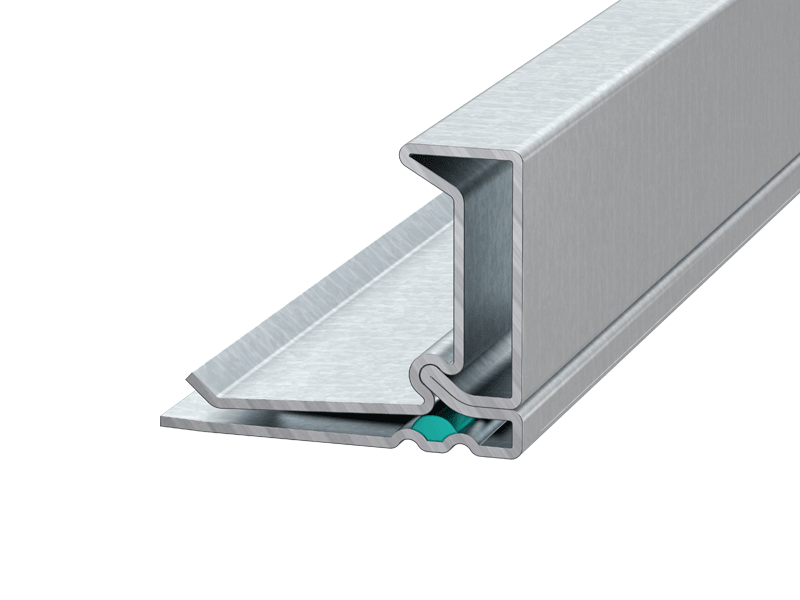

Numerous profiles such as thermally broken profiles, welded profiles, U-profiles, C-profiles, G-profiles, slotted tubes, etc.

Most common profile shapes

For many applications, it isn't necessary to develop new sections in order to generate an optimal solution. In such cases, the right profile can be selected from pre-existing, widely used profiles.

We are able to fall back on a large portfolio of common profile cross-sections. If the correct shape has not been implemented already, a small change to the cross sections of existing steel sections is usually sufficient.

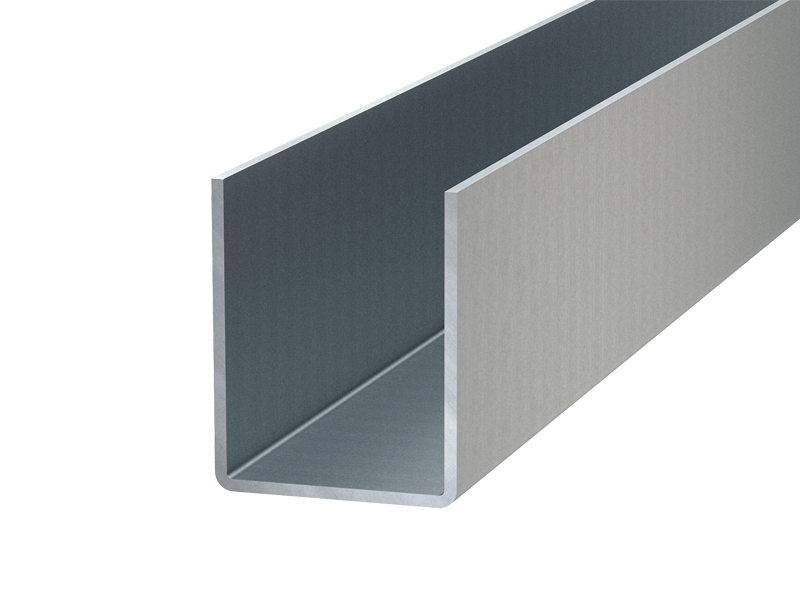

Channel sections

- Made of steel, stainless steel or non-ferrous metals (aluminium, brass, copper etc.)

- Different perforations possible

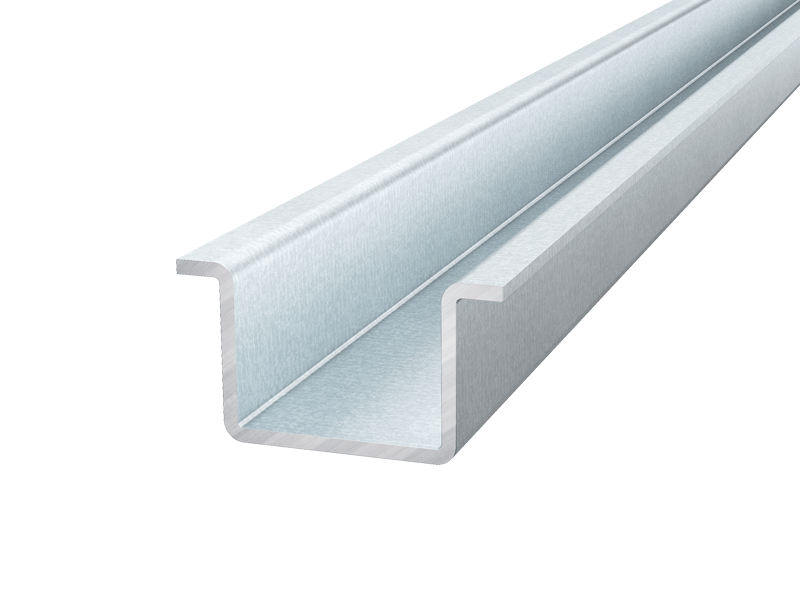

Double lip channels

- Made of steel, stainless steel or non-ferrous metals (aluminium, brass, copper etc.)

- In various shapes

- Different perforations possible

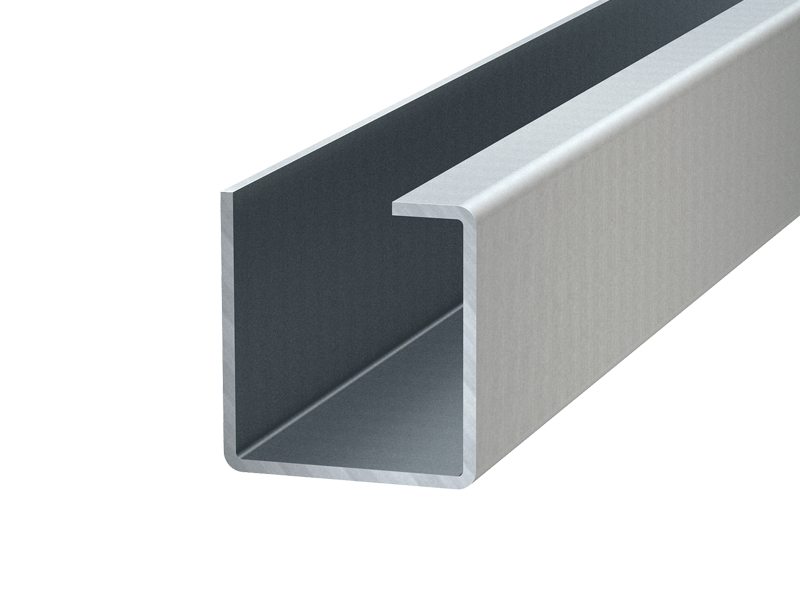

Single lip channels

- Made of steel, stainless steel or non-ferrous metals (aluminium, brass, copper etc.)

- In various shapes

- Different perforations possible

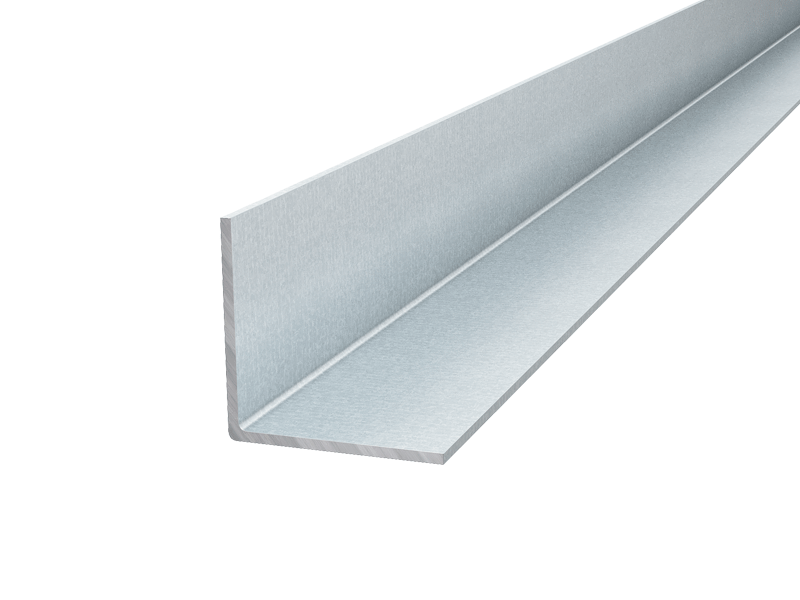

Angles / L sections

- Made of steel, stainless steel or non-ferrous metals (aluminium, brass, copper etc.)

- Material thicknesses from 0.5 to 3mm

- Different perforations possible

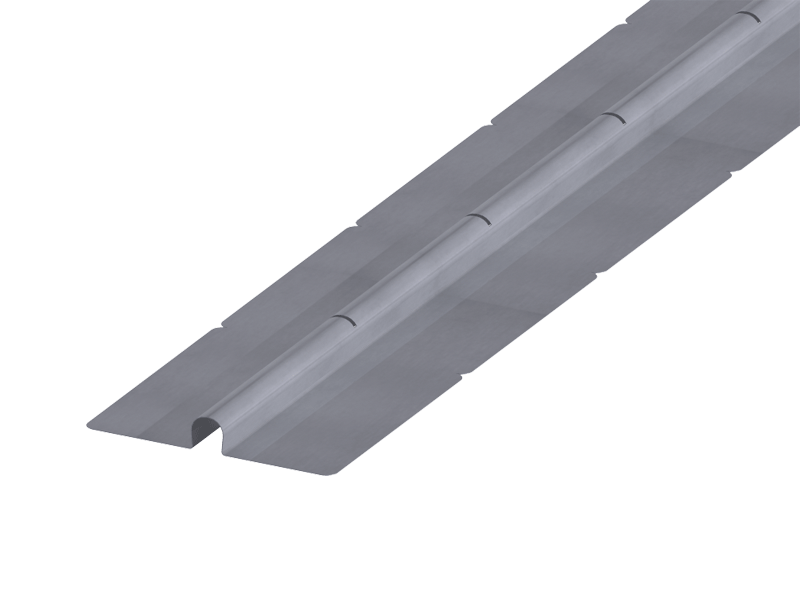

Top hat sections

- Steel hat profiles for construction

- Different perforations possible

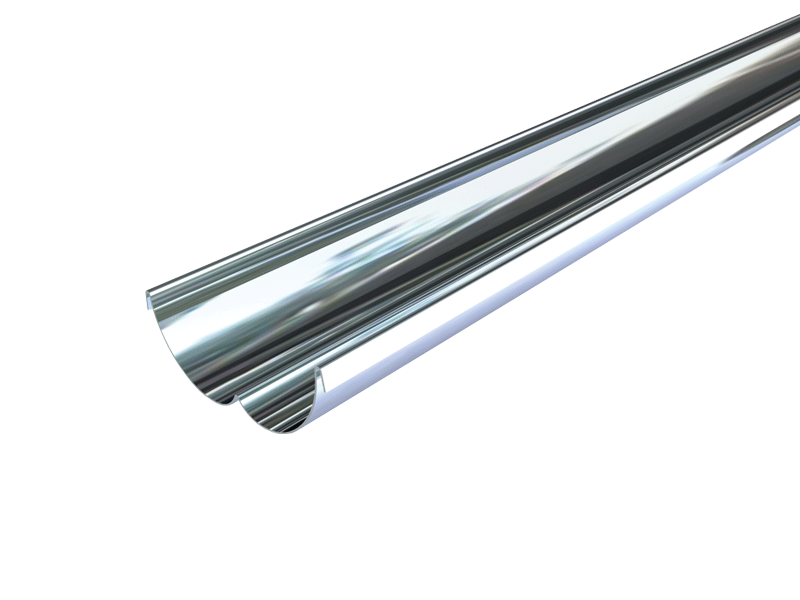

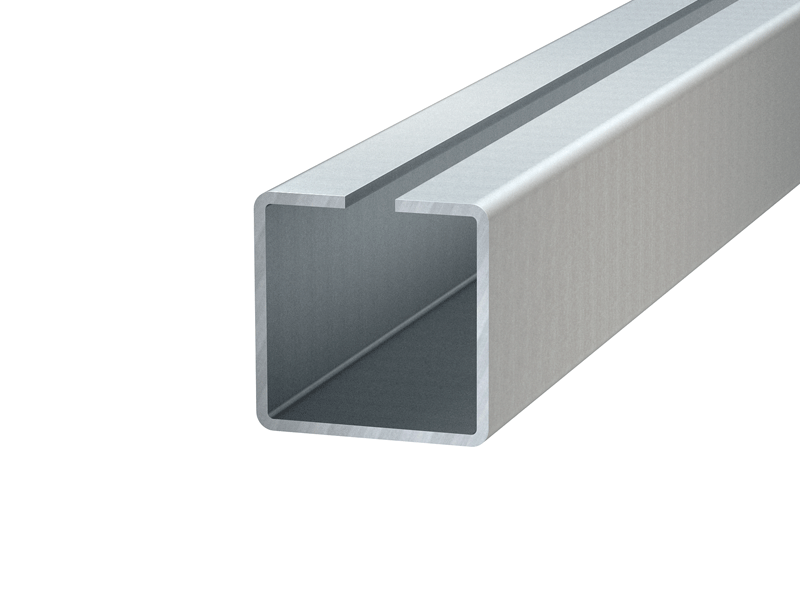

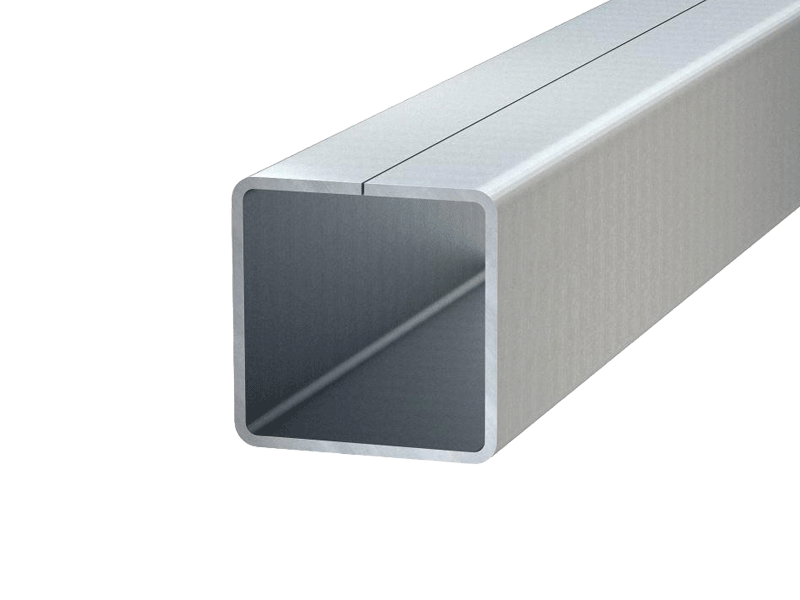

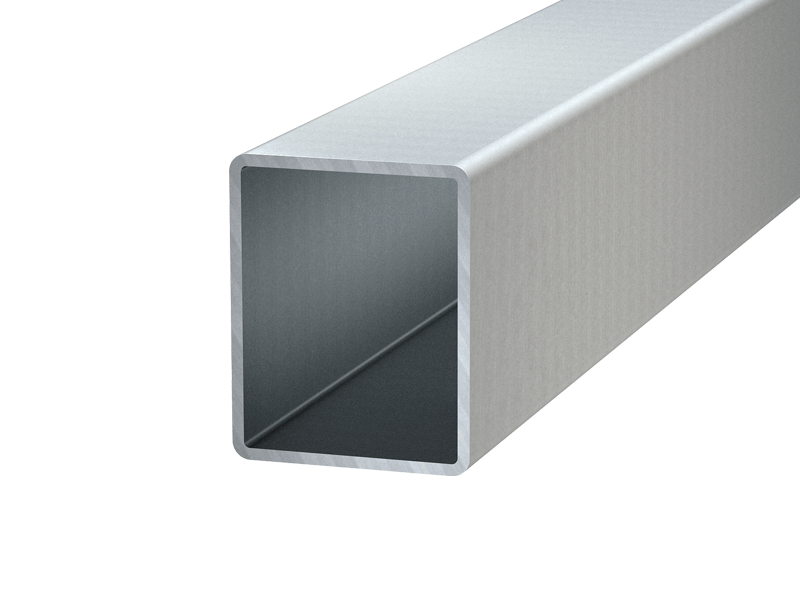

Closed box sections

- Steel slit tubes for high stability

- Material thicknesse from <1.0mm to 3mm possible

- Different perforations possible

Welded steel sections

- Welded square tubes

- Different perforations possible

- Metre cut possible

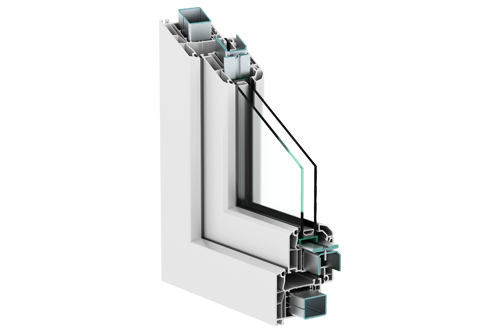

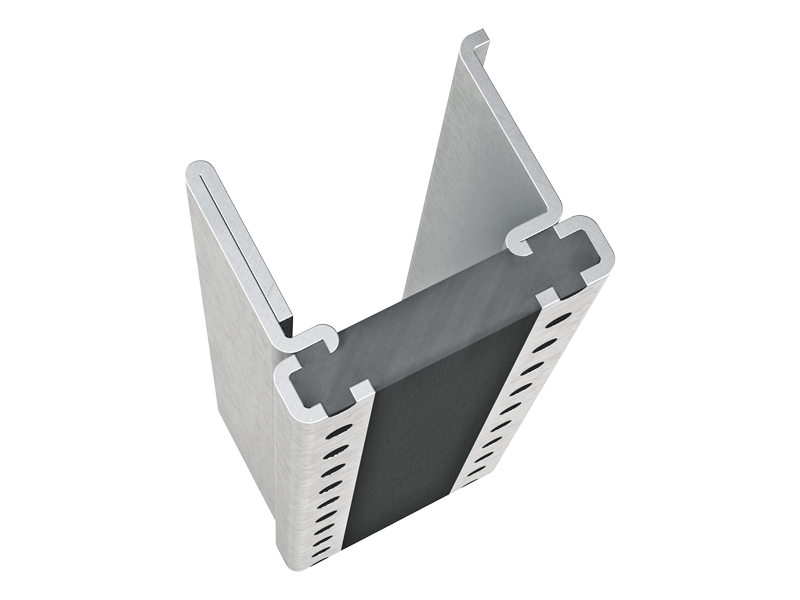

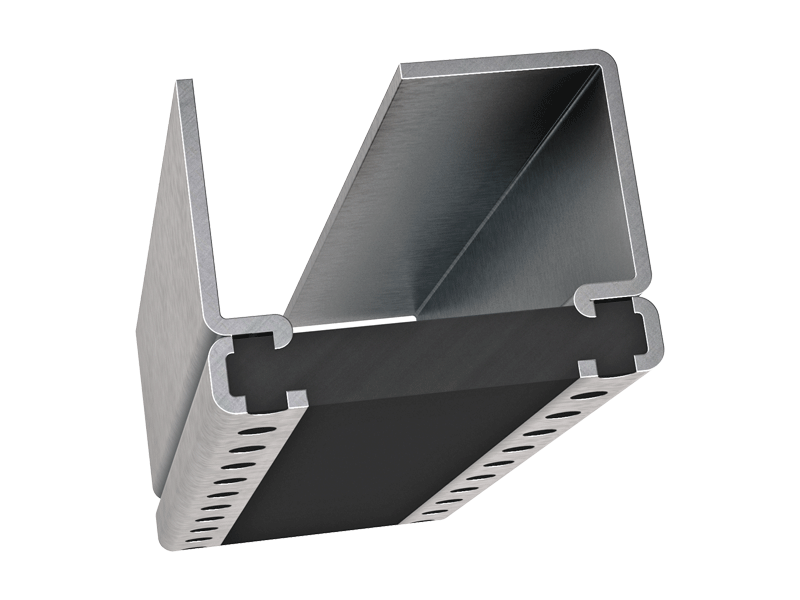

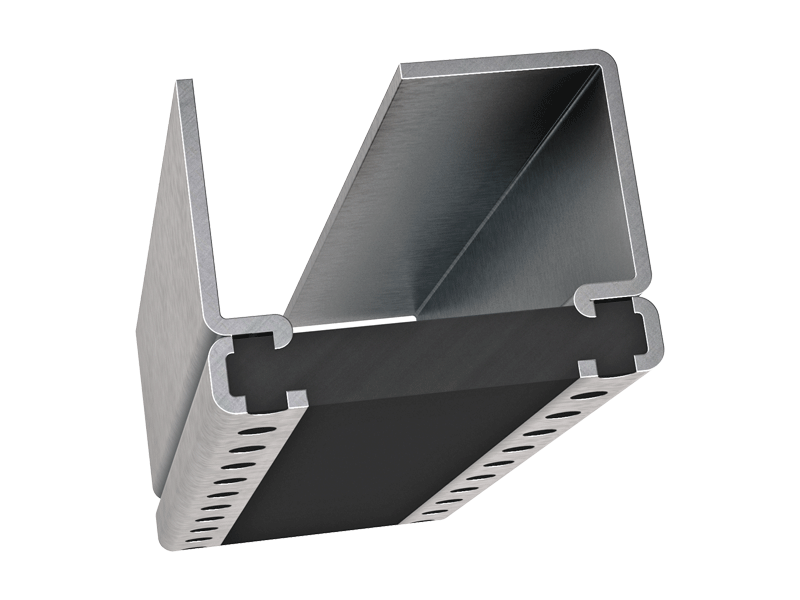

Thermally broken profiles

- Combination of roll-formed metal legs and a moulded polyurethane core

- Help to avoid cold gaps

- For insulated housings of air handling units, insulated partition walls or as reinforcements sections for PVCu and steel windows

Welded steel sections

- Welded square tubes

- Different perforations possible

- Metre cut possible

Thermally broken profiles

- Combination of roll-formed metal legs and a moulded polyurethane core

- Help to avoid cold gaps

- For insulated housings of air handling units, insulated partition walls or as reinforcements sections for PVCu and steel windows

Lorem Ipsum dolor sit amet

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.

WHAT WE CAN DO FOR YOU

Gebhardt-Stahl offers you more than just reinforcement profiles. Even if the production and optimisation of the reinforcement profiles are of course always in focus, there are also a number of other organisational measures or services that distinguish us as a supplier.

Therefore, we would like to give you a brief overview of the areas in which we strive to become even better for you every day:

- Innovation and quality

- Advice and support

- Calculation of the profiles

- Special variants and profiles as desired

- Well thought out logistics

- Fixed lengths

- Individual bundle sizes and packaging

Custom-rolled sections

Whenever standard profiles do not fit an application or a new developed product requires a completely new profile, our specialists in the design and production team are happy to assist.

We manufacture customised profiles even in small quantities, precisely rolled according to your specifications (galvanised steel starting at approx. 4 t., stainless steel starting at approx. 2 t.).

The great flexibility offered by the roll forming process and the ability to process steel (metal) strips on our machines with thicknesses between 0.1mm and 3,5mm and widths between 30mm and 850mm allows us to produce an enormous variety of profiles. The length of the profiles - from 50mm to 12.000mm - is only limited by the storage and transport possibilities.

From the idea to the implementation of your project, Gebhardt-Stahl supports and accompanies you with the experience and expertise of over 30 years in production. Close, partnership-based cooperation with our customers in the development of the special profiles enables optimum, rapid results through the transfer of knowledge and synergy effects.

OUR EXPERTS FOR BESPOKE PROFILES

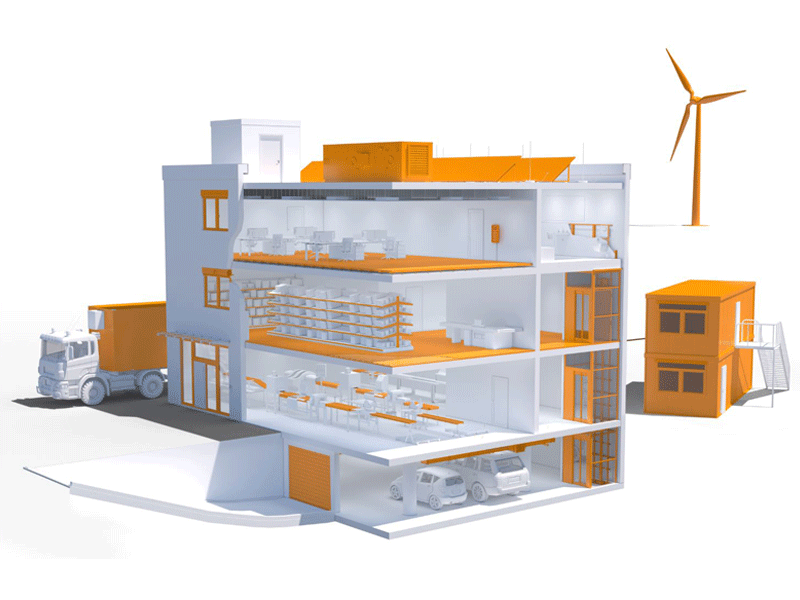

MARKETS AND INDUSTRIES

At Gebhardt-Stahl, we have been working in close cooperation with our customers for over 35 years to produce the optimum special profiles for the respective application. We already manufacture thousands of different profiles for the most diverse requirements.

The industries in which we are represented with our products are as diverse as our profiles. Steel profiles or profiles made of metal are used in many areas of everyday life and in the most diverse of

different branches of industry.

Cold-rolled special profiles play a "supporting role" not only in the construction industry but also in countless other areas. Mostly invisible in their function as a building material or construction material, cold-rolled metal profiles are also used as a design element in modern architecture.

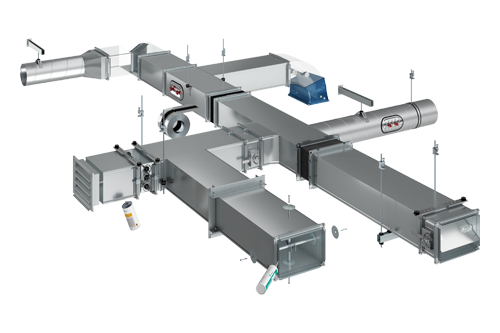

Our profiles are used, for example, in the following areas

raised floors

Underfloor heating

Shopfitting

Solar

Fastening technology

Lighting technology

Air conditioning

Gates & Doors

Container construction

Viticulture & fruit growing

RESOURCE CONSERVATION

Gebhardt-Stahl supports and accompanies you from the idea to the realisation of your project with the experience and know-how of over 35 years. The close and cooperative partnership with our customers in the development of the special profiles enables optimal and fast results through knowledge transfer and synergy effects and contributes to the conservation of resources.