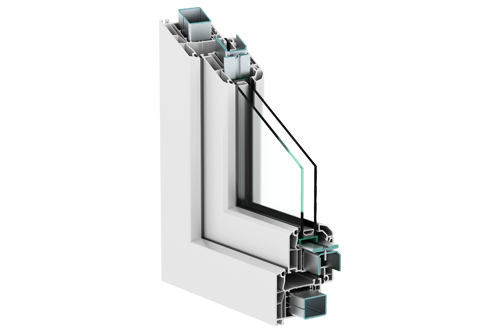

Thermally broken sections

The new Builidings Energy Act (GEG), the increased environmental awareness and rising energy costs lead to the fact that planners, operators and end-users are more and more demanding windows with better U values. Particular attention is paid to this aspect, especially with the construction of low-energy or passive houses.

Multi-chamber profiles with up to 7 chambers and multi-glazing (up to triple glazing) with an argon or krypton filling make it possible to achieve better U values. However, sometimes this is insufficient and too expensive.

Our protected thermally broken sections now offer the possibility to reduce the U values of windows further and to achieve this without structural compromises, even in the case of large elements.

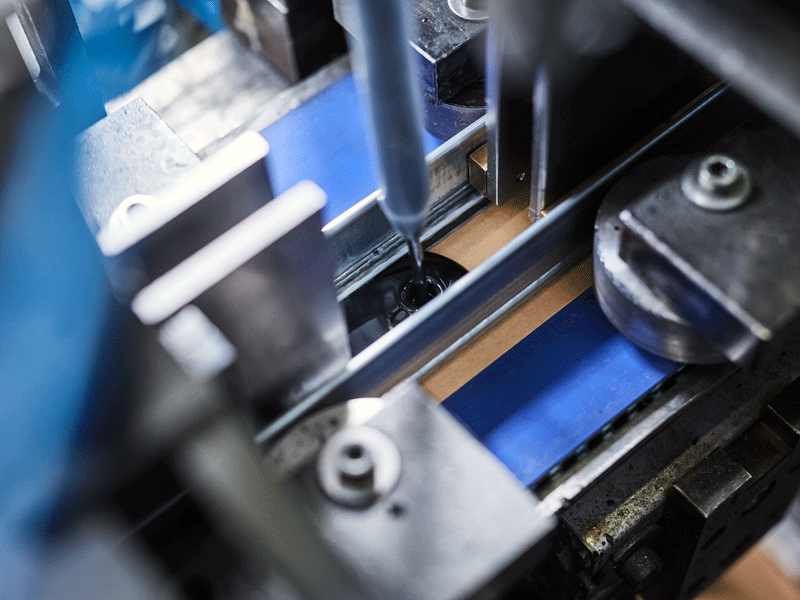

Screwable

Screw connections, which are otherwise performed in steel, can also be performed, as usual, in the plastic part of the thermally broken sections

Structure

In comparison with equivalent steel reinforcing profiles, the structure is similar

Production processes

Production processes can be maintained unchanged. No changes in the production process are necessary in order to build windows with different Uf values

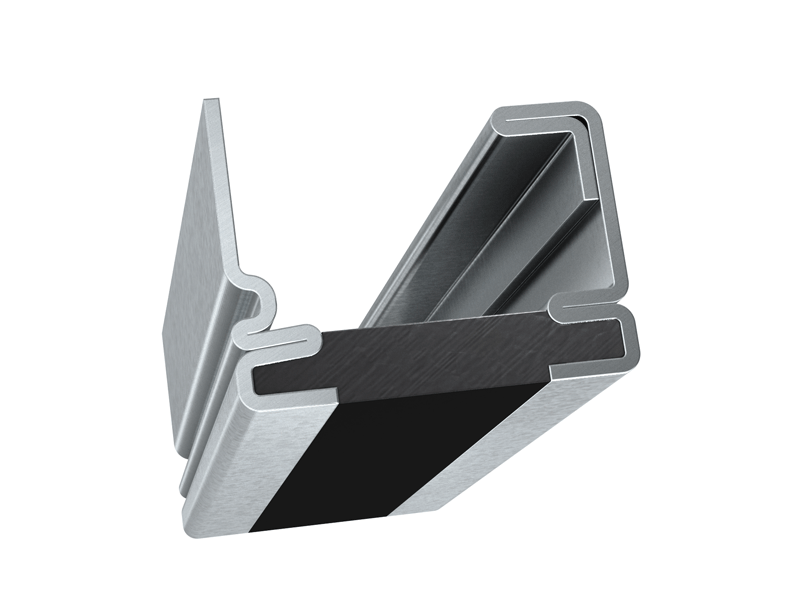

The thermally broken profiles consist of cold-rolled steel legs and a connecting polyurethane bridge, which is cast with the steel legs during production.

The IFT-certified thermally broken sections help to save energy and in doing so, conserve resources. They enable a Uf value reduction of up to 0.2 W/m2K to be achieved. In doing so, they significantly contribute to meeting the requirements of the energy saving regulation 2016 (EnEV)

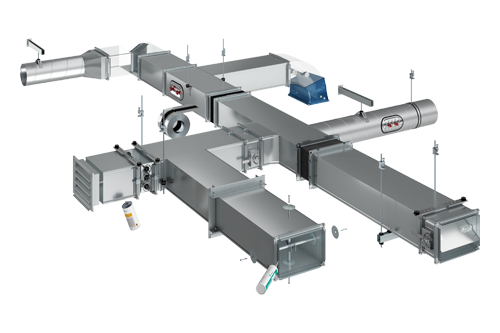

Universally applicable

Window construction, equipment construction, plant engineering etc.

Save time

Maintaining the production process

Energy saving

Thermally-separated profiles help to comply with the EnEV Directive 2016

Same processing

No machine conversion compared to profiles without thermal break

Conserving resources

Uf-value reduction up to 0.2 W/m²K

Powder coating

Thermally broken profiles are powder-coatable

WHAT WE CAN DO FOR YOU

Gebhardt-Stahl offers you more than just reinforcement profiles. Even if the production and optimisation of the reinforcement profiles are of course always in focus, there are also a number of other organisational measures or services that distinguish us as a supplier.

Therefore, we would like to give you a brief overview of the areas in which we strive to become even better for you every day:

- Innovation and quality

- Advice and support

- Calculation of profiles

- Special variants and profiles according to your wishes

- Sophisticated logistics

- Fixed lengths

- Individual bundle sizes and packaging