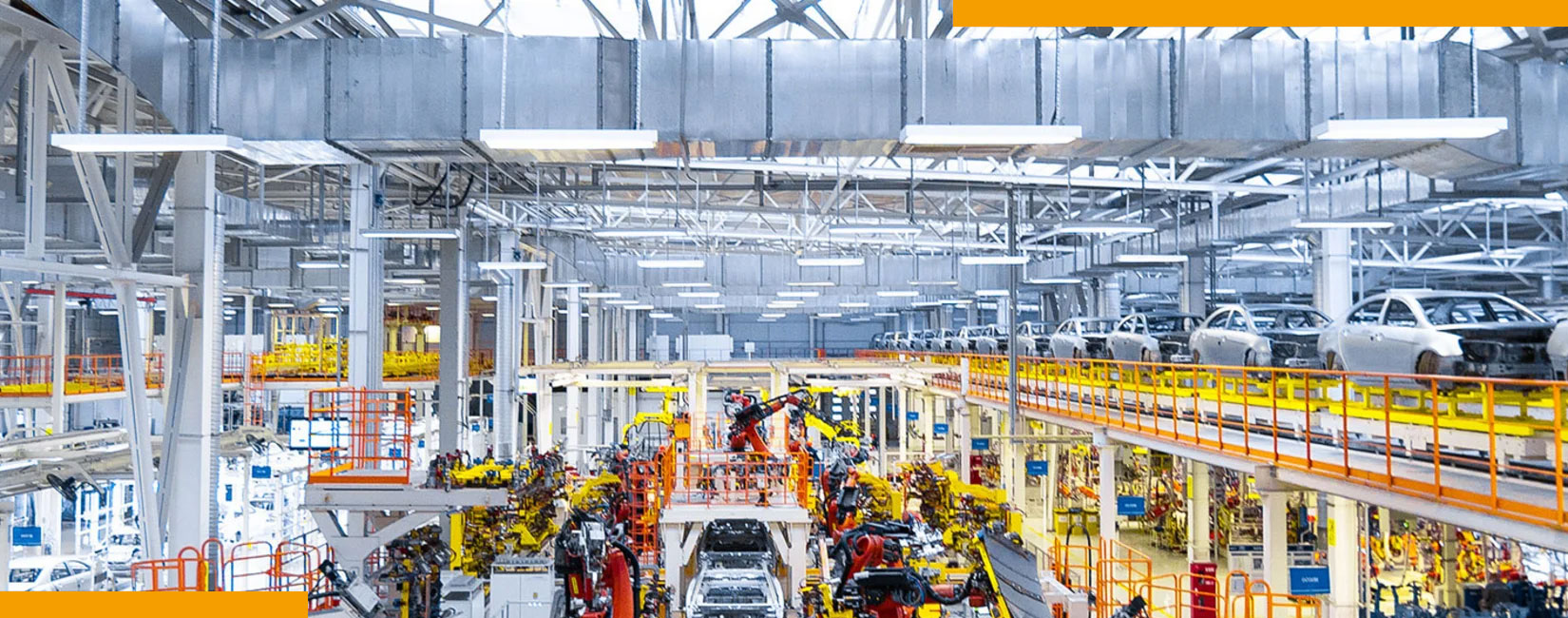

Industrial and production sites

In industrial manufacturing facilities, air ducts are essential – they ensure clean air, safe working conditions, and stable production processes. Yet the demands on these systems are as diverse as the industries themselves: from temperature resistance and fire protection to chemical durability, air ducts must meet the highest technical and regulatory standards.

Air ducts under extreme conditions

Industry is never one-size-fits-all – and that’s especially true for air technology. The requirements for air ducts vary greatly depending on the sector, production processes, and spatial conditions:

- Food and pharmaceutical industries: Hygiene, cleanability, and corrosion resistance take top priority. Air ducts must be made from materials that are easy to clean and do not release particles or germs.

- Chemical and petrochemical industries: Here, ducts are exposed to aggressive gases and vapors. Materials must be chemically resistant and airtight to prevent leaks and hazards.

- Metalworking, foundries, glass industry: Extreme temperatures, dust, and mechanical stress dominate. Air ducts need to be exceptionally robust, heat-resistant, and low-maintenance.

- Electronics and semiconductor manufacturing: In cleanrooms, precise airflow is critical. Ducts must be particle-free, antistatic, and allow exact control.

Temperature stability as a key factor

Extreme heat demands extreme reliability. In high-temperature industrial processes – from melting furnaces to thermal treatment systems – air ducts play a critical role in safety and efficiency. That’s why our solutions are engineered to deliver:

- Premium heat-resistant materials like stainless steel, galvanized steel, and advanced high-temperature polymers.

- Effective insulation to minimize energy loss and protect surrounding components.

- Uncompromising stability under thermal expansion and cyclical stress.

Failure is not an option. With the right components and expert installation, you ensure uninterrupted production and maximum safety – even under the toughest conditions.

Standards-compliant systems for critical situations

Fire safety starts with the right air duct system. In the event of a fire, ducts can accelerate the spread of flames and smoke – especially when they pass through multiple fire zones. That’s why fire protection is a top priority in planning and installation. Our solutions deliver:

- Non-combustible materials such as galvanized steel or aluminum for maximum safety.

- Automatic fire dampers that close instantly in case of fire, preventing the spread of flames and smoke.

Quality you can rely on

As a trusted supplier of industrial air duct systems, we offer a comprehensive portfolio designed for the most demanding applications. Our range includes:

- Air duct components made from heat-resistant materials, suitable for temperatures exceeding 600 °C.

- Fire-protection-certified parts, tested and approved according to the latest standards.

- Seals and fasteners that deliver reliable performance even under high temperatures and vibration.

- Custom solutions for explosion-risk zones, fully ATEX-compliant and documented.

- Mounting accessories and fastening systems for safe, efficient installation.

Engineered for performance. Certified for safety. Built for your toughest challenges.

FAQ

No. We do not manufacture air ducts. Our customers – typically ventilation or plant engineers – produce the ducts themselves and use our products for their design and installation.

Yes. Our components are designed for high airflow rates, large cross-sections, and extended duct systems – ideal for expansive industrial and warehouse spaces.

Yes. Our components are robust, durable, and suitable for use in dusty, humid, or temperature-stressed industrial environments.

We offer components suitable for use in fire safety-critical areas – such as fire-resistant materials and products compatible with fire protection systems.

Our components are designed for fast, safe, and cost-efficient installation – even under challenging conditions such as great heights or limited access.

Do you have questions?

Give us a call. Or write us an email. We're here to help.