Efficiency starts with the right technology

In air duct manufacturing, every second counts – and every connection. To remain competitive today, you need machines that not only think for themselves, but also work with you. This is exactly where we come in: with a machine portfolio specially tailored to the requirements of air duct production, service and maintenance.

Efficiency, precision and flexibility for your production

In air duct manufacturing, every detail counts – from the precise connection of individual components to the standard-compliant leak test. Our machine solutions are specifically developed for the requirements in production, service, and maintenance of air duct systems. They enable our customers to work faster, more flexibly, and more efficiently – both in the workshop and directly on the construction site.

Whether you manufacture, assemble, or test air ducts – we offer you the right machines that simplify your processes and increase your productivity.

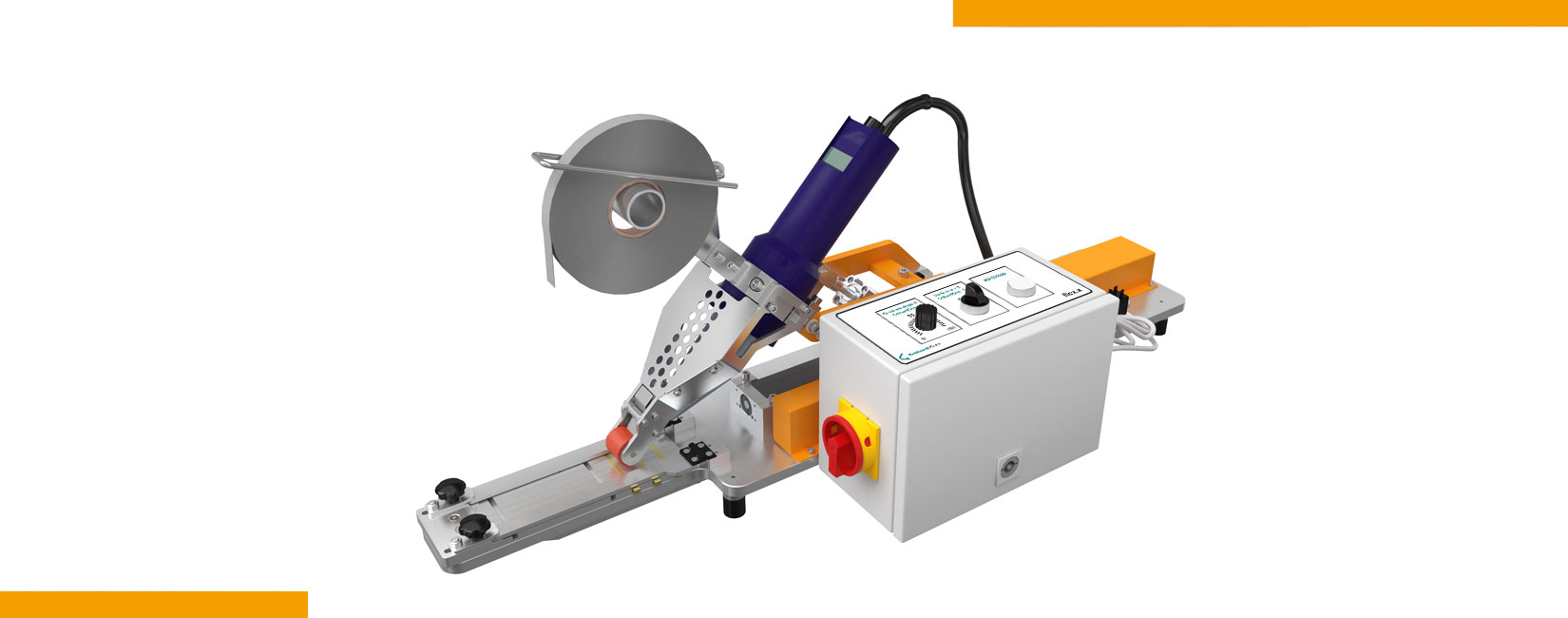

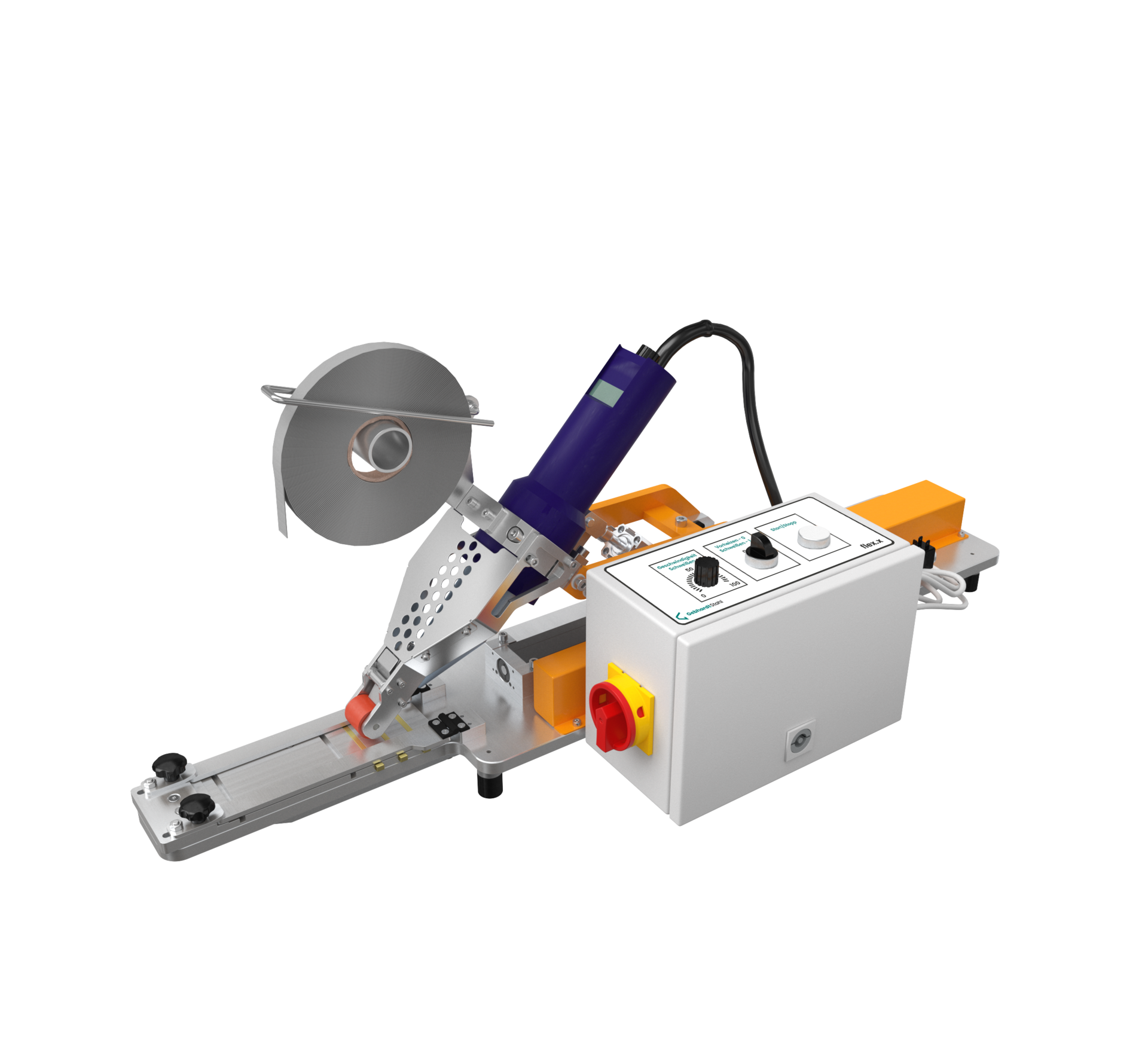

Hot Air Welding Machine

For safe and clean welding of flex.x connectors (duct connectors)

Our flex.x hot air welding machine impresses with its high-quality workmanship and intuitive handling, which works reliably even under construction site conditions. It was specially developed for connecting our flex.x connectors and ensures a permanent, airtight connection

- Robust construction for daily use

- Easy to operate – even for inexperienced users

- Uniform weld seams for maximum tightness

Leak proof tester

Detect leaks – comply with standards – ensure quality

Our Mobile leak proof tester enables quick and precise determination of air leakage volumes in air duct systems in accordance with DIN EN 13779, DIN EN 1507, DIN EN 12237 and DW 144. It is easy to use, comes in a sturdy carrying case and is ideal for use on construction sites. The handy carrying case for hoses and accessories makes mobile use even easier. Thanks to the integrated thermal printer and USB connection, measurement results can be documented directly and processed digitally.

- Compact, mobile and ready for immediate use

- Integrated thermal printer for direct report output

- Ideal for quality assurance and acceptance tests

Pneumatic punch press

Connecting frames – no retooling, no tool changes

The pneumatic punch press is the perfect solution for fast and secure connection of air duct frame joints.

Thanks to a universal tool holder, 20, 30, and 40 mm frames can be processed without adjustments – saving time and reducing potential sources of error.

Your benefits:

- No tool change required

- High process reliability through precise punching

- Suitable for all common frame sizes

Do you have questions?

Give us a call. Or write us an email. We're here to help.

Ronny Krüger

Contact

Gebhardt Group Air Duct Solutions

Our air duct and HVAC components are part of the Gebhardt Group Air Duct Solutions division, which leverages an international network of leading brands. This enables us to offer you tailored solutions, high-quality products, and comprehensive services for the manufacturing, installation, and maintenance of your air ducts – locally, regionally, and globally.