Save energy with thermally broken sections

Thermally broken sections are the key to energy-saving windows. Thanks to modern thermal break with polyurethane, these steel profiles ensure significantly greater energy efficiency. They allow the Uf value to be reduced by up to 15 % - for lower heat loss and lower heating costs.

The energy plus for strong PVC-U windows and doors

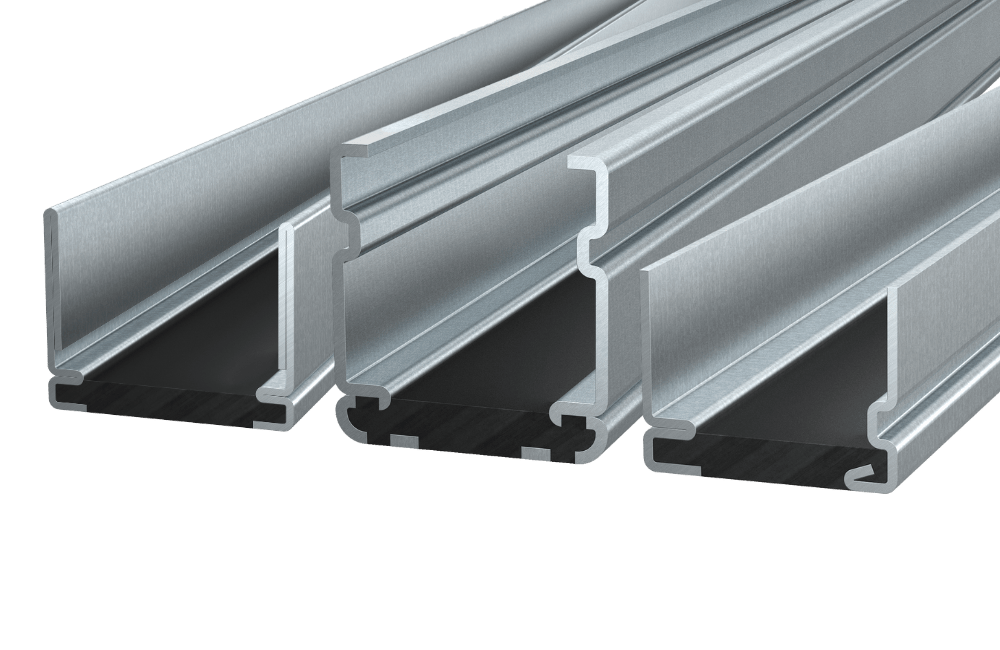

The profile solutions consist of perforated steel legs and a connecting polyurethane bridge, which is securely moulded with the steel legs during production. Polyurethane (PU) is a robust plastic with very good thermal insulation properties. The profiles make a measurable contribution to reducing energy losses and utilising resources efficiently. A real plus point, especially with rising energy prices.

- With a possible Uf value reduction of up to 0.2 W/m²K, they noticeably improve thermal insulation

- They help to fulfil the strict requirements of the German Building Energy Act (GEG)

- Ideal for windows and doors as well as industrial gates

Recommended for passive houses

Passive houses contribute significantly to climate protection and long-term energy savings. Roll formed thermally broken sections play a key role in preventing thermal bridges, meeting passive house standards, minimising energy use, and maintaining a comfortable indoor climate.

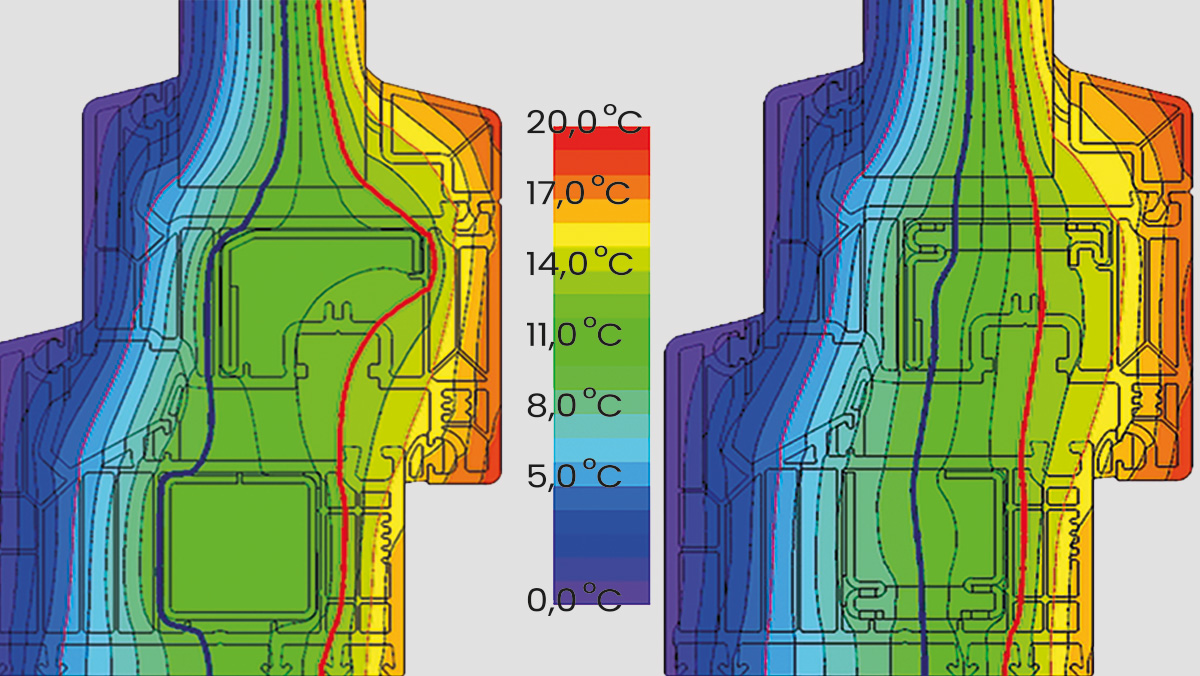

Isothermal curves compared

The difference in the isothermal curve of a window cross-section is clearly visible through the use of thermally broken sections. While conventional reinforcement profiles create thermal bridges, our IFT-certified thermally broken profiles create a barrier against heat loss.

Gebhardt Group Construction

Our thermally broken sections are part of the Gebhardt Group Construction division, which has access to an international network of leading brands. This enables us to offer you customised solutions, high-quality products and comprehensive services for the construction industry - locally, regionally and globally.