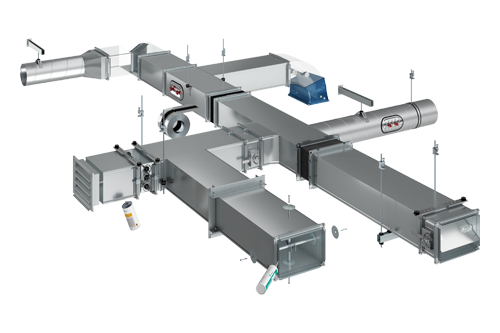

HVAC COMPONENTS

EVERYTHING FROM A SINGLE SOURCE

Our focus on continuous development has allowed us to grow over the past decades from a supplier of HVAC components to a leading company in the field of slip-on flanges and a full-range supplier in the field of ventilation accessories. In the course of this development, however, one thing has always been in the foreground - the pursuit of professional, high-quality and individual solutions for you, our customers and partners.

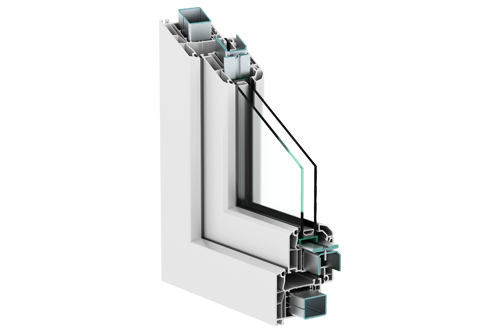

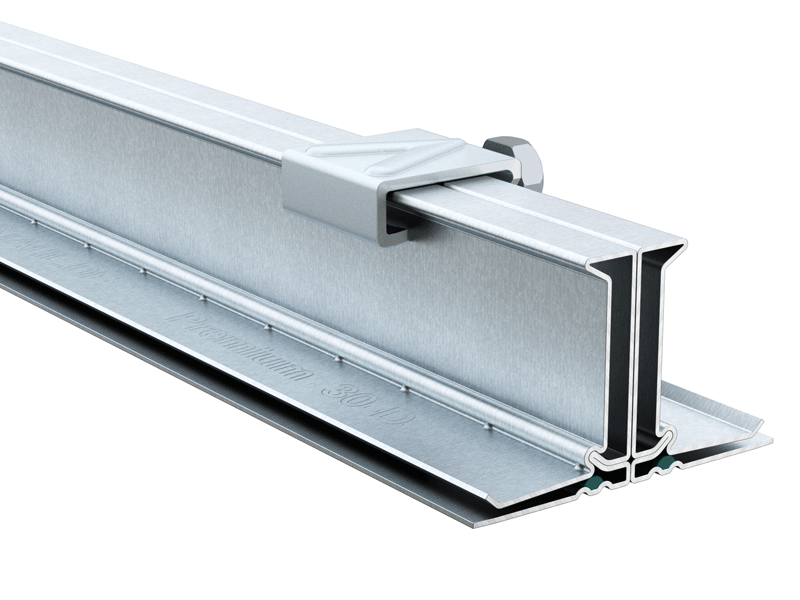

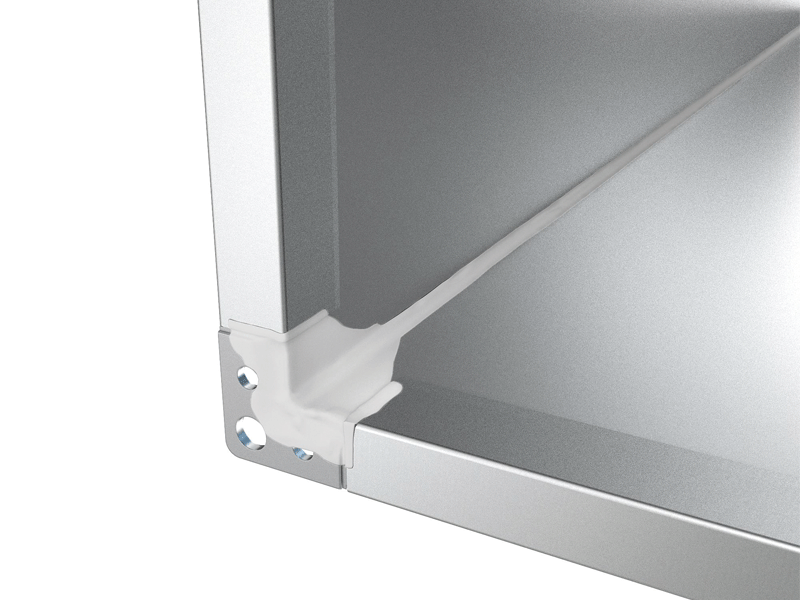

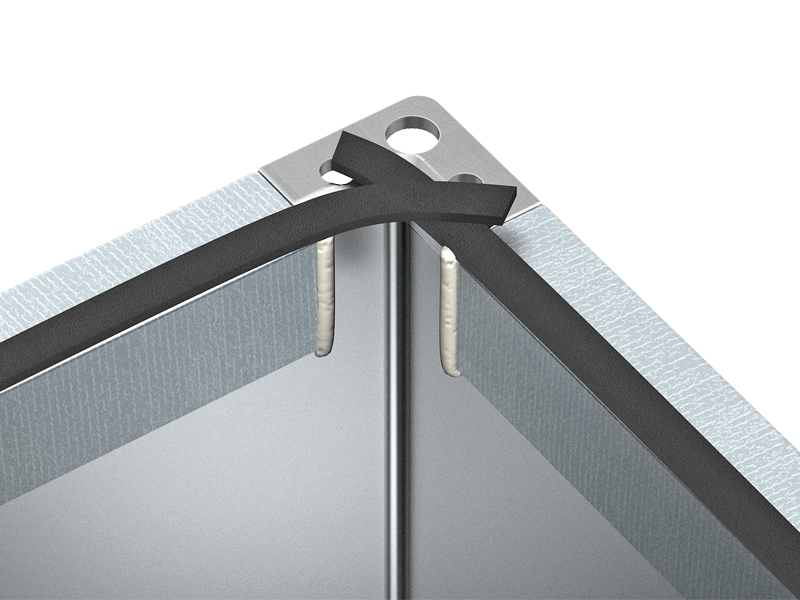

Our high-quality air duct profile systems, consisting of flange profiles and various mounting brackets specially developed for our profiles, form the central component of our range for you. Together, these two components form a unit that meets the highest requirements for quality and tightness.

In addition to our first-class air duct profile systems, you will find everything you need for high-quality and professional production and installation of the individual components in our range.

MANUFACTURING

HIGHEST DEMANDS ON QUALITY AND TIGHTNESS

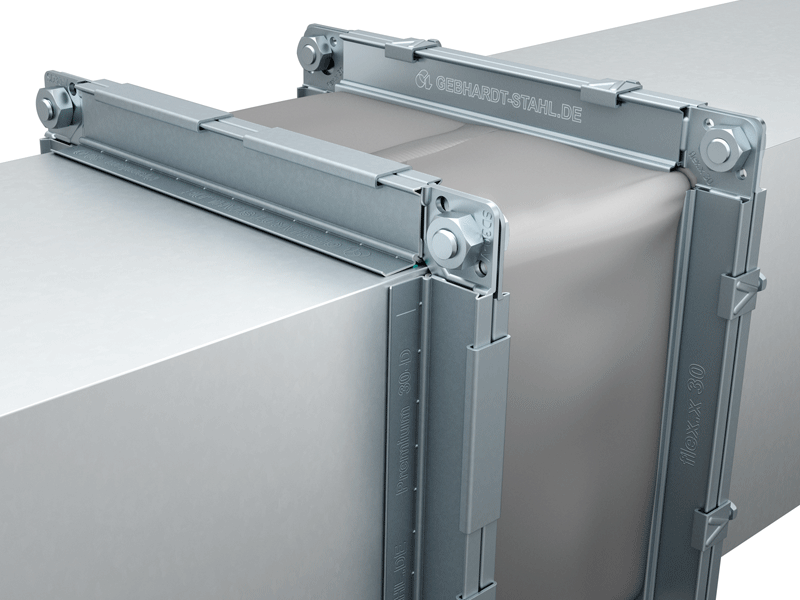

Gebhardt –Stahl slip-on duct connections enable the fast, cost-effective and tight connection of rectangular air ducts. Almost any size and sealing class is possible. Comprising of slip-on duct flanges of different sizes and a variety of different corners, our 4-bolt connection systems allow for the appropriate connecting frame to be produced for every requirement (duct size, volume flow, pressure ratios, air tightness). Flanges and corners are also available made of stainless steel (AISI 304 or AISI 316) or aluminium.

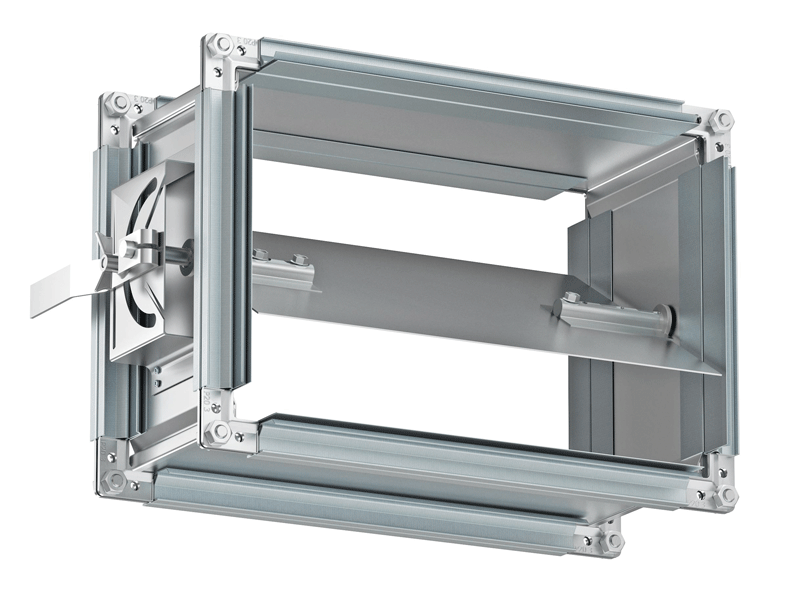

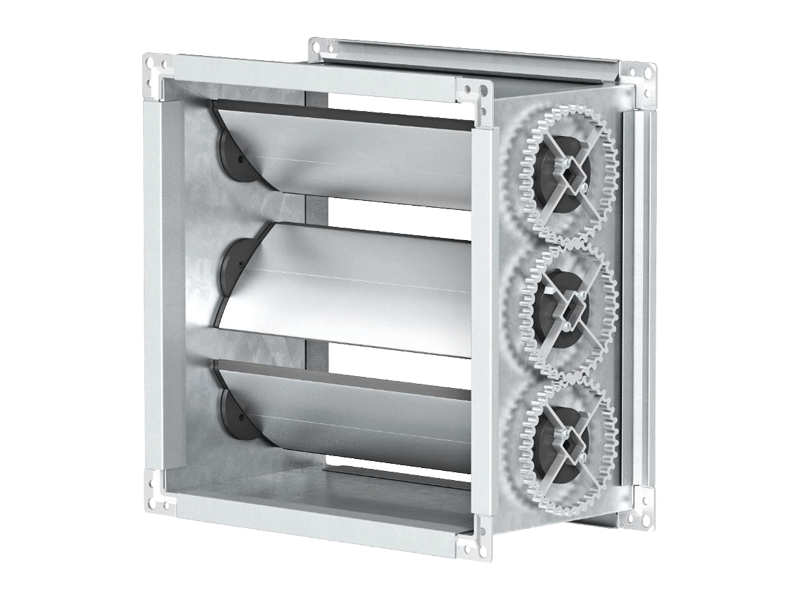

OPTIMISES THE FLOW - REDUCES TURBULENCES AND NOISE

Turning vanes are installed in rectangular ductwork, e.g. in bends or junctions, in order to optimise the air flow. The turning vanes effectively reduce turbulence and consequently, pressure losses and noise. The use of turning vanes is specified by DIN EN 1505 for bends with an angle greater than 45°. As such, the number of vanes depends on duct dimensions. In contrast, for junctions, the German DIN standard does not specify if the use of turning vanes is of any useful purpose there.

Turning vane fasteners, available in galvanised steel and stainless steel, are ideal for fixing the turning vanes. In order to reduce the leakage, all our baffle plugs are already fitted with a mounted sealing washer.

For maximum seal requirements, we provide sealing pads for our turning vane fasteners. Additionally we offer a reinforcement profile for turning vanes for reducing vibrations at the end of the turning vanes.

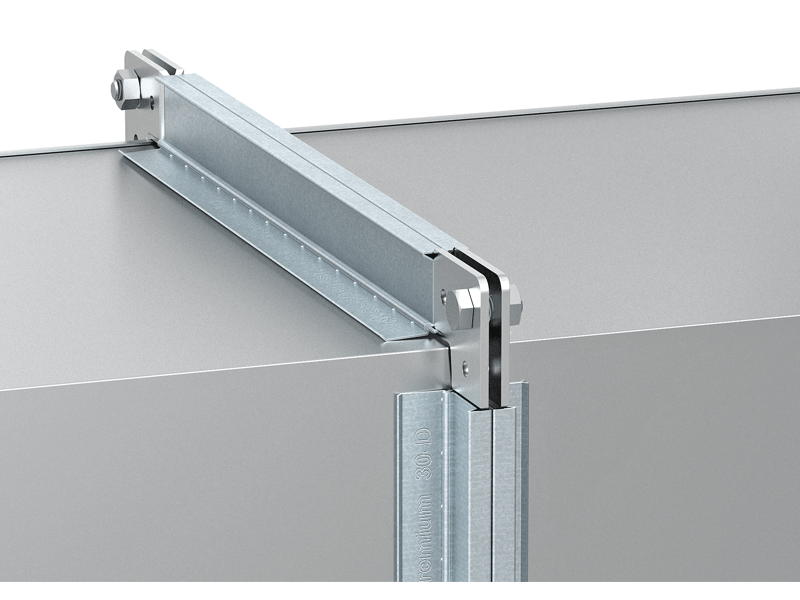

AVOIDS VIBRATIONS AND NOISE

Turbulences and vibrations can cause disturbing vibrational noises to ductwork. In order to avoid these noises, the best possible damping and stiffening of the ductwork is required. Rectangular straight ducts with unfavourable duct cross-sections, with high positive or negative pressure and, of course, in case of large duct cross sections do need reinforcement measures.

Ventilation ducts with a large cross-section and varying excess pressure and negative pressure should be optimally stiffened in order to ensure maximum stability and elimination of flutter. The additional reinforcements then ensure that the duct sections remain dimensionally stable and that the entire ventilation system can be operated smoothly without pressure losses/leaks and, above all, safely.Gebhardt-Stahl reinforcement materials are easy to use and cost-effective.

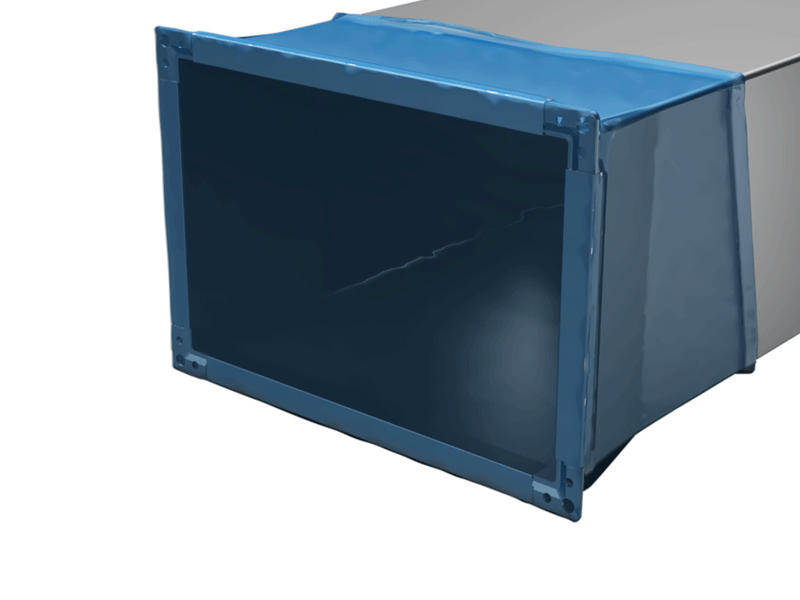

SHEET. FABRIC. SHEET

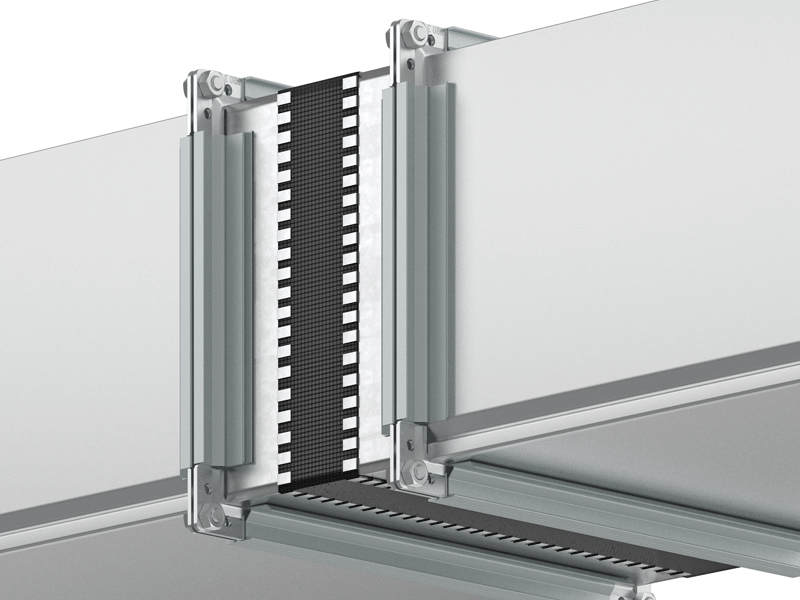

Flexible connectors are necessary for making fabric compensators. These compensators help to avoid the transmission of vibrations in spiral or rectangular ductwork and suitable for acoustic decoupling. Thus, flexible connectors frequently serve as a connecting element between devices or fans and ventilation ducts.

Flexible connectors consist of a fabric, e.g. polyester with PVC coating or glass fibre with PU coating, which is secured to sheet metal on both sides. The sheet metal can be made of galvanised steel or stainless steel.

If assembled correctly, the produced compensators are suitable for sealing class C.

INSTALLATION

UNIVERSALLY APPLICABLE - HIGH LOAD CAPACITY

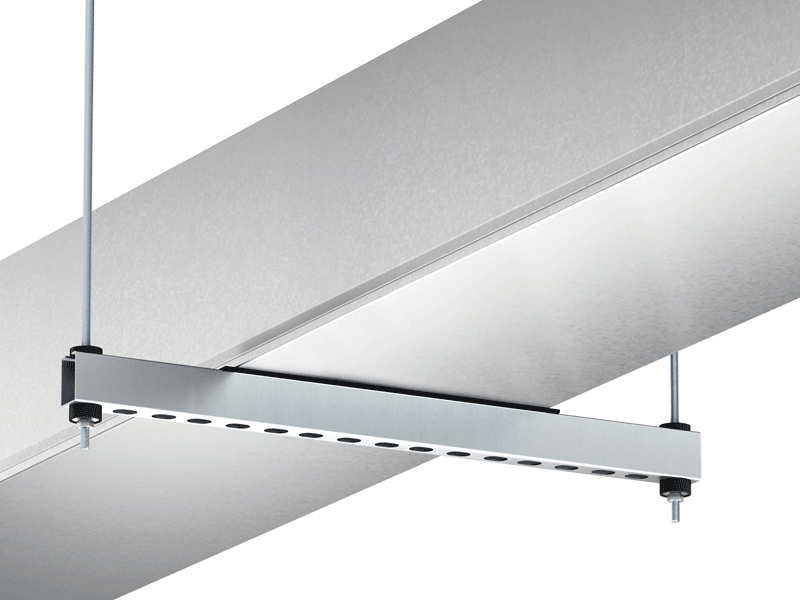

Thanks to the combination perforation with round and slotted holes, our mounting rail proves to be a versatile solution for the professional and simple suspension of angular ventilation ducts. To ensure a high load-bearing capacity and the best statics, all our mounting rails are made of 1.75 mm thick galvanised slit strip.

As an option, you will find matching insulating rubbers in our range to prevent a sound bridge or sound decoupling, as well as end caps for a visually clean finish to the mounting rail and to reduce the risk of injury at cut edges.

STRONG. SAFE. RELIABLE.

To ensure that your air ducts remain tight even with longer edge lengths and strong pressures, we recommend the use of our sliding strips or threaded clamps. In order to meet your individual requirements, you will find sliding strips and duct clamps of the most varied designs in our portfolio, as well as liner and cold shrink tapes in different sizes.

The selection of a suitable tape and its correct use are also of great importance when it comes to the tightness of a connection in air duct construction.

HOLD EACH COMPONENT IN PLACE

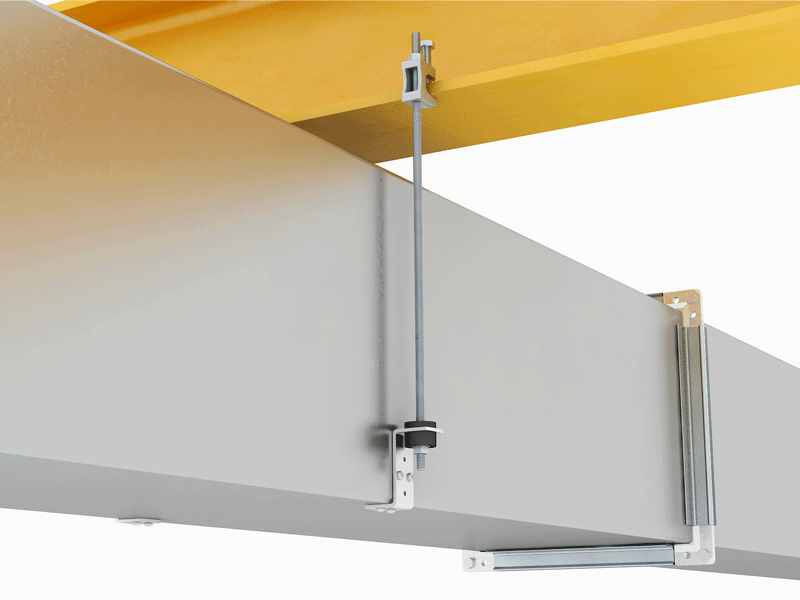

Support angles and hangers are the common products for suspension of rectangular or spiral ducts. They are usually attached to the ductwork by screws or rivets.Hangers are a cost-effective and easy-to-use solution for the suspension of ventilation ducts.

The Gebhardt support angles and hangers are fully assembled with improved sound insulation and have been tested to DIN 4109 (structure-borne sound test on request) The average improvement is: Between 125 Hz and 4000 Hz: 7 dB; Between 500 Hz and 4000 Hz: 10 dB (tested by the Institut für Schall- und Wärmeschutz, Essen). All hangers and support angles are galvanised and assembled with a patented, screwable insulation element with washer. Suitable for use of threaded rods Ø 10 mm.

ACCESSORIES

NO MATTER WHETHER SQUARE OR ROUND - WE HAVE THE MATCHING ACCESS DOOR

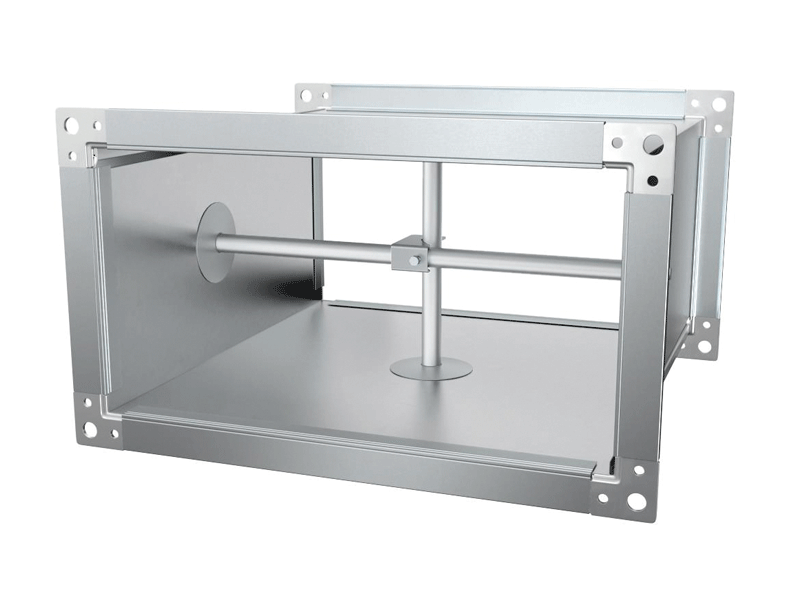

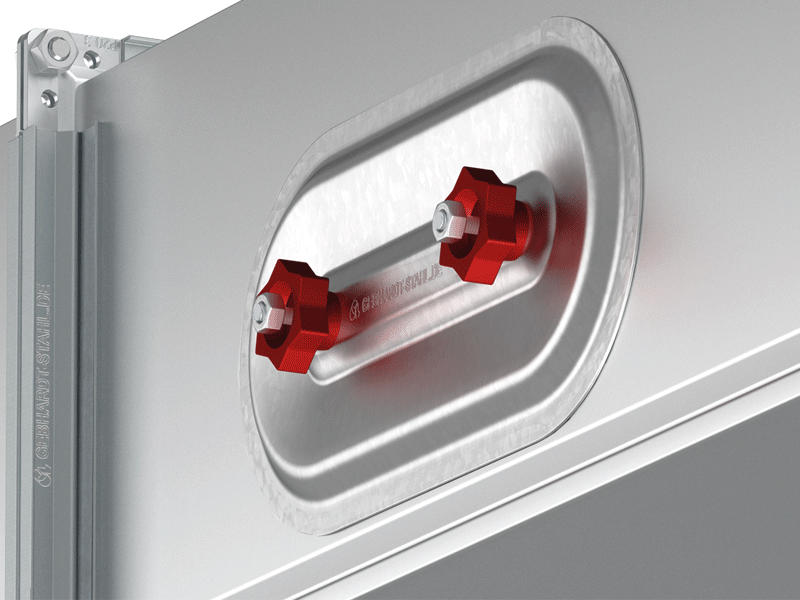

Our access doors are pressed from galvanised steel or stainless steel in a sturdy double-shell design with a flow-optimised inner shell to prevent turbulences.

Two star-shaped hand knobs with embedded metal threat allow to fix the access panels to the duct. A polyethylene foam gasket securely seals the access panels, so they are suitable for sealing class D (TÜV-Nord certified).

INDISPENSABLE WHEN IT COMES TO HYGIENE

Protective duct cover is a self-adhesive polyethylene film, which is adapted to the specific requirements of HVAC systems. The tear-resistant film protects ductwork against dust and contamination during storage and transportation. It has particularly good adhesion properties on galvanised steel sheets and stainless steel and is suitable for sealing duct components according to VDI 6022.

The Gebhardt protective duct cover is weather-resistant, UV-resistant and can be removed quickly and without residue.

CHEMICAL-TECHNICAL

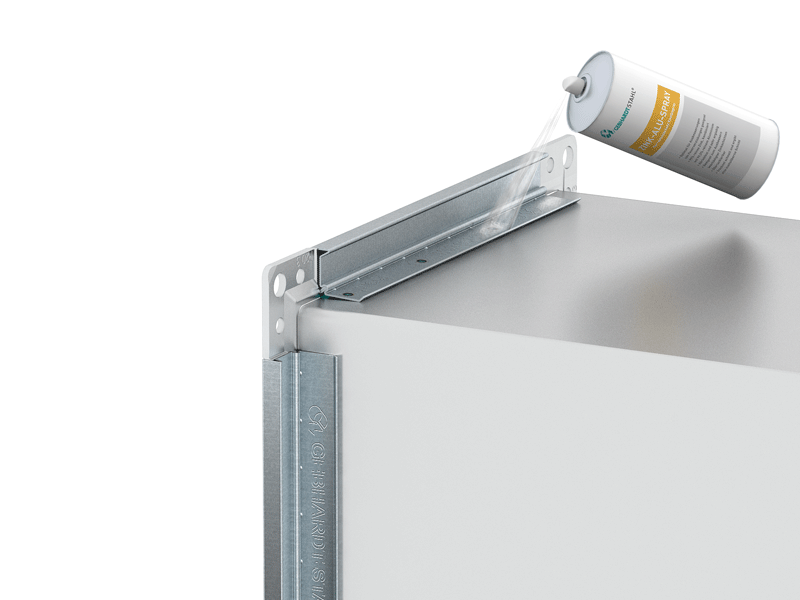

SPECIAL SEALANTS FOR INDIVIDUAL REQUIREMENTS

WHEN IT HAS TO BE TIGHT

In order to achieve the requirements of air tightness classes C or even D, the quality and processing of the duct sealing tape is sometimes decisive. Our sealing tapes are characterised by easy handling and high quality.

In addition, most of the sealing tapes can be used in accordance with the hygiene guideline VDI 6022 and are therefore permissible for a wide range of applications.

SELF-ASSEMBLY SYSTEMS

VARIABLE SELF-ASSEMBLY SYSTEM FOR THE PRODUCTION OF FLEXIBLE CONNECTIONS

Thanks to our flex.x system, you have the option of manufacturing expansion joints or elastic connection spigots (canvas spigots) yourself and all that in the usual quality. Our self-assembly kits for flexible connections are suitable for the highest air tightness requirements and are airtight - without any additional sealing tape. The self-assembly systems are suitable for both square and round air ducts, as well as for connection with our proven sliding strips or duct clips.

The finished expansion joints are used, among other things, as expansion compensation and for structure-borne sound decoupling on air ducts or RLT systems.

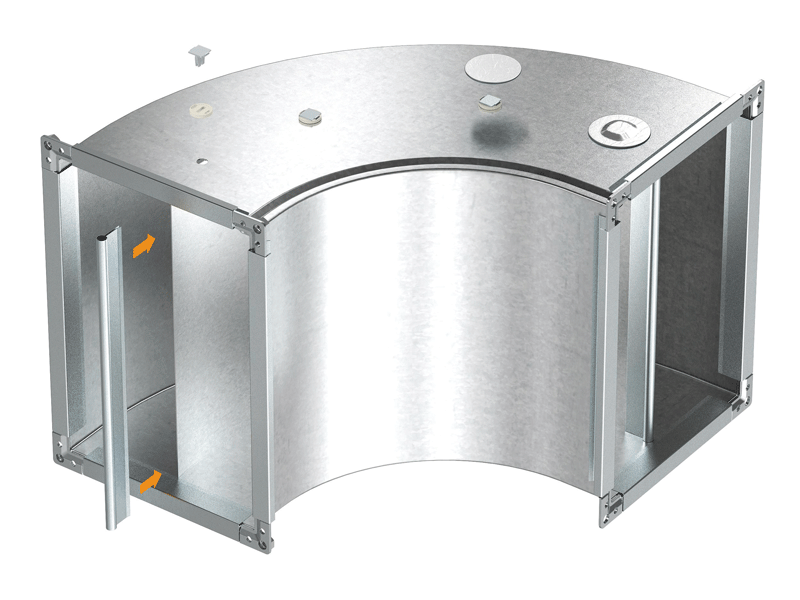

TO PROTECT AGAINST THE INTRUSION OF RAIN, LEAVES AND BIRDS

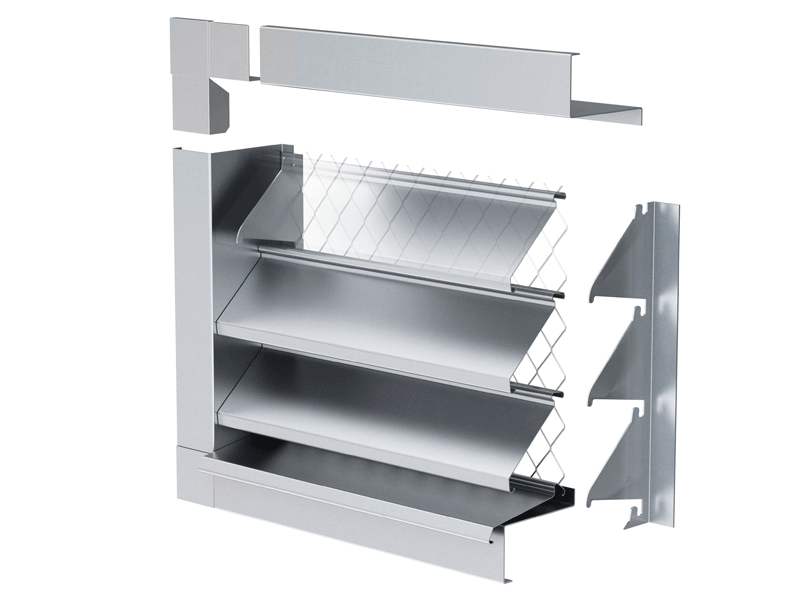

Our weather louvre is a variable plug-in system that consists of a slat profile, frame profile, matching corner brackets and a slat support. The weather protection grille self-assembly system is available in galvanised steel, stainless steel and aluminium.

Weather louvres of various sizes can be produced quickly and easily. For very large weather protection louvres, it is recommended to manufacture the element as a multi-part louvre to achieve even greater stability. By the way, the slat support can also function as a centre bar.

The all-round frame covers broken edges at the wall opening and ensures a clean wall finish. However, the frame can also be dispensed with for installation in ducts or units.